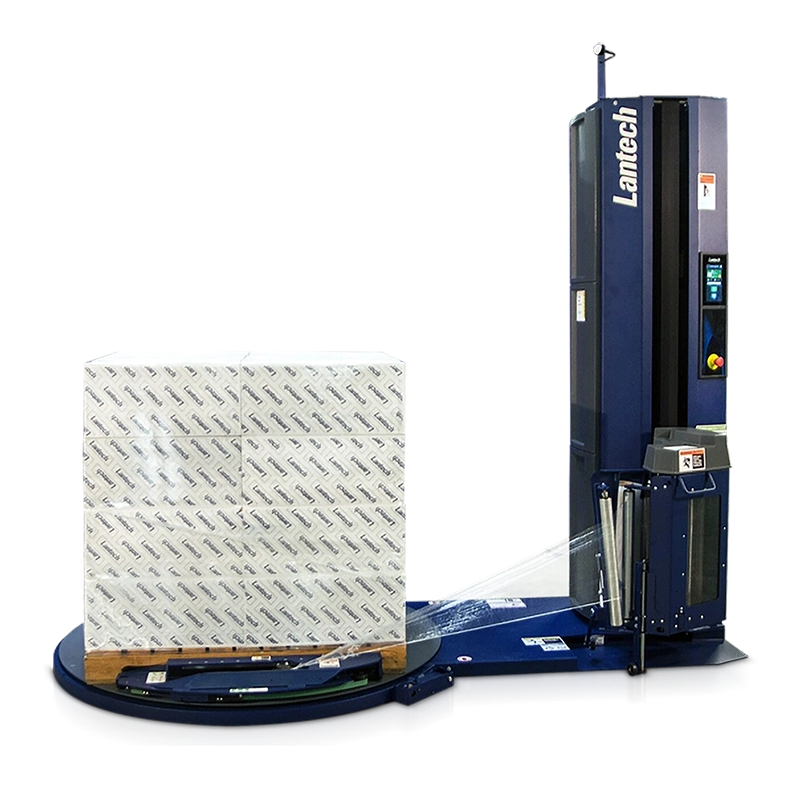

Lantech QL-400 with EZ Weigh Integrated Scale

Wrap and weigh in one easy step!

Enhance Your Strapping Machine with the Lantech EZ Weigh Integrated Scale

Optimise your packaging process and ensure precise load weights with the Lantech EZ Weigh Integrated Scale, the perfect add-on for your strapping machine. Designed for seamless integration and exceptional accuracy, the EZ Weigh scale helps streamline operations, improve load consistency, and enhance overall efficiency. Make your packaging process smarter and more reliable with the EZ Weigh Integrated Scale from Lantech.

48″ Diameter Urethane Race

Provides broad balanced support and resists shock-loading meaning no metal-to-metal wear.

Microcontroller

- Intuitive, easy to understand controls regardless of language or skill

- Easily fine-tune wrap patterns with presets

Quick Reference Guide

- Located on the machine

- Includes trouble-shooting, operating, and adjustment guides

E-Z Thread Roll Carriage

- Rollers are fully shielded from hands

- Roll carriage on same side as controls, easy to load and reduces risk of injury

Key Benefits of Using Lantech EZ Weigh with Your Strapping Machine

- Accurate Weight Measurement: Achieve precise load weights every time, ensuring compliance with shipping regulations and preventing overcharges.

- Enhanced Efficiency: Integrate weighing directly into the wrapping process, reducing the need for separate weighing stations and saving valuable time.

- Improved Load Consistency: Ensure consistent packaging quality and stability by accurately measuring and adjusting load weights.

- Streamlined Operations: Simplify your workflow with an all-in-one solution that combines strapping and weighing in a single step.

- Cost Savings: Reduce the risk of shipping penalties and material waste by using exact weight measurements for each load.

- User-Friendly Interface: Enjoy easy operation and quick setup with the intuitive control panel and clear display.

- Robust and Durable: Built to withstand the rigors of industrial environments, the EZ Weigh scale is designed for long-lasting performance and reliability.

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.