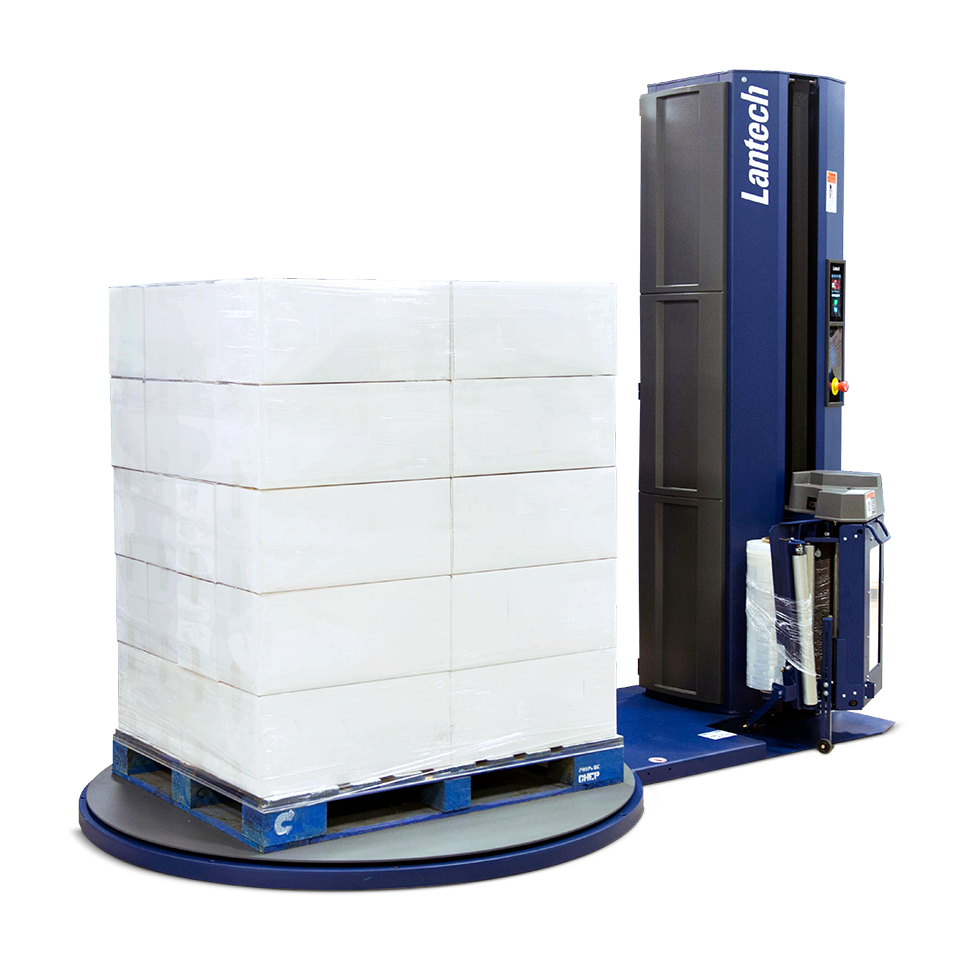

Lantech QL-400

Intelligent, Intuitive & Instructional Stretch Wrapping Machine

The Most Advanced Semi-Automatic Stretch Wrapper on the Market

QL-400 Stretch Wrapper automatically attaches and cuts the film. Equipped with a fully protected mechanical cut and clamp. Improve productivity by keeping the operator on the forklift.

Affordable Automation

48″ Diameter Urethane Race

Provides broad balanced support and resists shock-loading meaning no metal-to-metal wear.

Microcontroller

- Intuitive, easy to understand controls regardless of language or skill

- Easily fine-tune wrap patterns with presets

Quick Reference Guide

- Located on the machine

- Includes trouble-shooting, operating, and adjustment guides

E-Z Thread Roll Carriage

- Rollers are fully shielded from hands

- Roll carriage on same side as controls, easy to load and reduces risk of injury

Productivity

- Automation in a Semi-automatic stretch wrapping environment.

- Efficient film usage to lower operational costs using patented XT Cut and Clamp® automatically captures the stretch film and cuts it at the end of the wrap cycle.

- Protected by Load Guardian – Creates, maintains and delivers Safe-to-Ship Loads.

- Designed to handle a variety of load sizes and shapes.

- Durable construction for long-term reliability using energy-efficient components.

- Fully Mechanical, requires no air of hot wire.

- Industry leading 3 year warranty.

Load Guardian

A patented control system that will create, maintain and deliver safe-to-ship loads every time!

Load Guardian is Lantech’s patented control system that ensures the right containment force for safe-to-ship loads every time. It reduces operator involvement and removes the guesswork from stretch wrapping any load configuration. Safe-To-Ship loads with Load Guardian® consistently and effortlessly deliver the correct containment force for any load configuration. Paired with Pallet Grip®, it secures products to the pallet, ensuring they arrive at their destination in their original condition.

- Creates and saves profiles during start-up or as needed.

- Automatically maintains consistent profile standards.

- Consistently applies the correct containment force across the entire load.

- Reduces the need for operator skill and intervention.

- Ensures predictable and repeatable film costs.

Available Options

Lantech makes wrapping pallets easier than ever before.

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Lantech Semi-Automatic Stretch Wrappers

Specifications

Performance |

|

|---|---|

| Peak Production Speed | Up to 30-40 loads/hr |

| Load Size Diagonal (Recommended) | 1750 mm (69″) |

| Maximum Load Wrap Height | 2030 mm (80″) |

| Maximum Load Weight | 1814 kg (4000 lbs) |

Performance Features |

|

|---|---|

| XT Cut and Clamp® | Standard |

| Auto Film Cut-off™ | Not Applicable |

| Pallet Grip® | Optional |

| Intelli-Sensor | Standard |

| Standard Film Width | 500 mm (20″) |

| EZ Thread Film Delivery | Standard |

| Standard Pre-Stretch | 200% |

| Wrap Force | Variable (Electric) |

| Film Capacity | 250 mm (10″) Roll Diameter |

| Film Delivery System | Power Roller-Stretch |

| EZ Weigh™ Integrated Scale | Optional |

Load Handling |

|

|---|---|

| Turntable Speed (Variable) | 12 RPM |

| Turntable Size | 1651 mm (65″) diameter |

| Turntable Drive | 3/4 HP TEFC |

Weight and Size |

|

|---|---|

| Approximate Shipping Weight | 680 kg (1500 lb) |

| Size | 3023 mm L 1702 mm W 2337 mm H (119″ L x 67″ W x 92″ H) |

Service Requirements |

|

|---|---|

| Pneumatic | Not available |

| Dedicated Electric Service Req. | 220 VAC 16 Amp |

Warranty |

|

|---|---|

| 3 Year. Unlimited cycles. All components covered. |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.