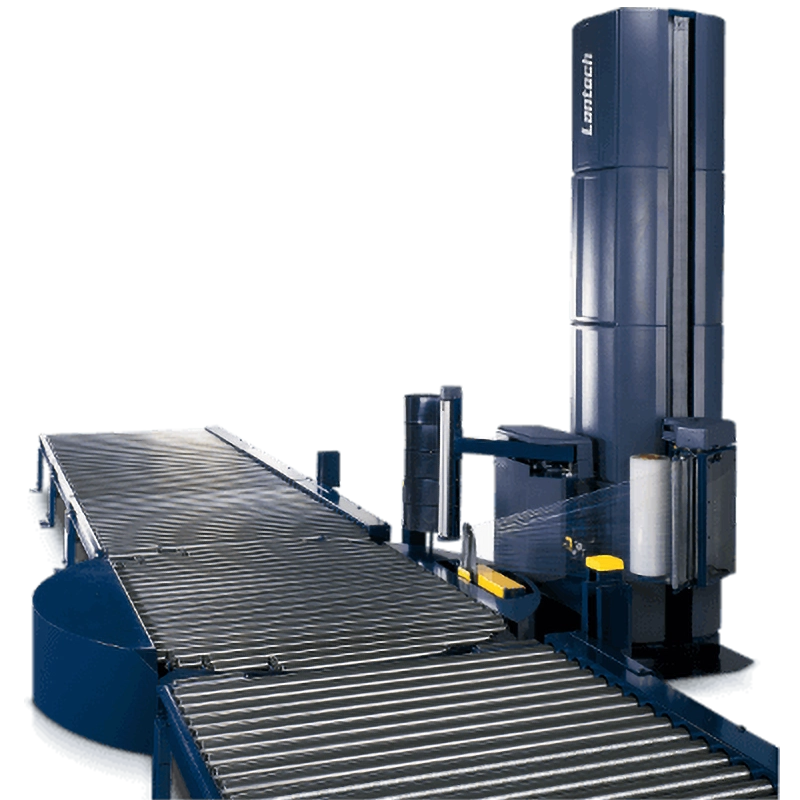

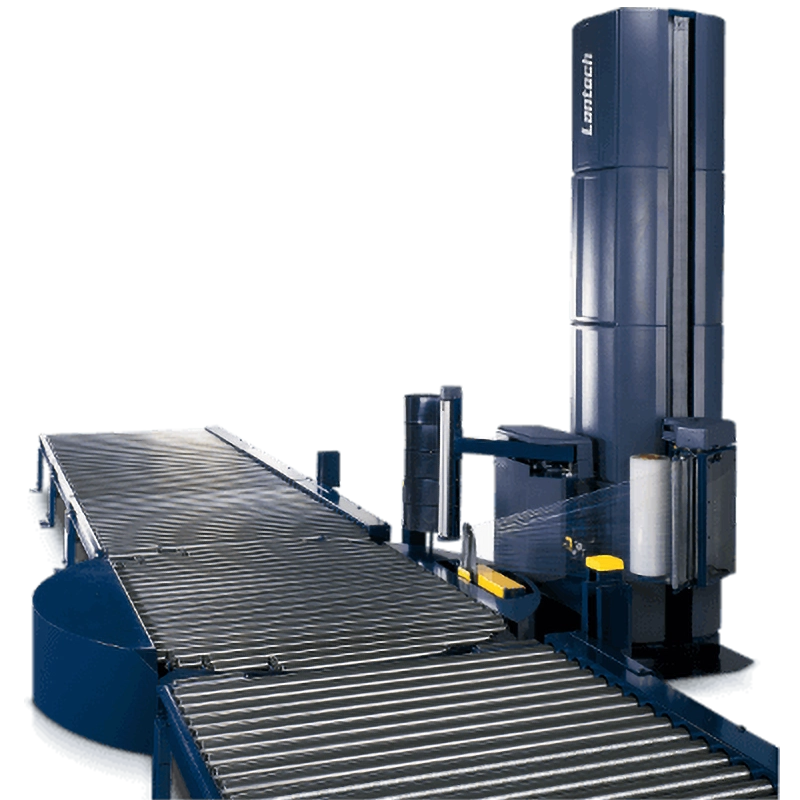

Lantech Q Automatic

Fully Automatic Stretch Wrapper to help customers increase productivity.

The Q-Automatic is designed to enhance packaging efficiency and reliability.

Maximise your packaging efficiency with the Q-Automatic Stretch Wrapping Machine, a state-of-the-art solution designed to streamline your wrapping process and ensure the secure transport of your products. With advanced technology and user-friendly features, the Q-Automatic is your ideal partner for optimal productivity and consistent, reliable performance.

48″ Diameter Urethane Race

Provides broad balanced support and resists shock-loading meaning no metal-to-metal wear.

Microcontroller

- Intuitive, easy to understand controls regardless of language or skill

- Easily fine-tune wrap patterns with presets

Quick Reference Guide

- Located on the machine

- Includes trouble-shooting, operating, and adjustment guides

E-Z Thread Roll Carriage

- Rollers are fully shielded from hands

- Roll carriage on same side as controls, easy to load and reduces risk of injury

Productivity

- Handles 45-60 loads per hour.

- Can be integrated with existing conveyor systems or used standalone.

- User-Friendly with safe side-access film loading and touchless film cutting.

- Easy-to-use Lan-Logix™ control panel.

- Durable Build with industrial-duty conveyor with 4000 lbs. capacity.

- Safety Features include complete system guarding, transition photocells for safety shutdowns.

- Customisable Options for high-speed package, increased load capacity, washdown, cold/freezer packages, corrosive duty package, extended wrap height, and modular electric top platen.

- Industry leading 3 year warranty, unlimited-cycle warranty.

Available Options

Lantech makes wrapping pallets easier than ever before.

Fully Automatic Stretch Wrapper

Fully Automatic Stretch Wrapper

Fully Automatic Stretch Wrapper

Fully Automatic Stretch Wrapper

Fully Automatic Stretch Wrapper

Lantech Stretch Wrapping Machines

Lantech Stretch Wrapping Machines

Lantech Stretch Wrapping Machines

Lantech Stretch Wrapping Machines

Lantech Stretch Wrapping Machines

Specifications

Performance |

|

|---|---|

| Peak Production Speed | Up to 45 loads/hr |

| Maximum Load Weight | 1814 kg (4000 lbs) |

| Maximum Load Wrap Height | 2030 mm (80″) |

| Maximum Load Weight | 1814 kg (4000 lbs) |

Load Handling |

|

|---|---|

| Turntable Speed (Variable) | 12 RPM |

| Turntable Size | 1321 mm Effective Width, 2057 mm Diameter (52″ EW, 81″ D) |

| Turntable Drive | .075 kW (1hp) 180 VDC Motor w/ Brake |

Performance Features |

|

|---|---|

| Pallet Grip® | Standard |

| Load Guardian | Not Available |

| Standard Film Width | 200% (100-300% Available) |

| Wrap Force | Electronic Control |

| Film Capacity | Power Roller Stretch |

| Automation Unit | Film – Reach Arm with Impulsed Hot Wire Film Clamp, Cutter |

| EZ Weigh™ Integrated Scale | Optional |

Load Handling |

|

|---|---|

| Turntable Speed (Variable) | 12 RPM |

| Turntable Size | 1651 mm (65″) diameter |

| Turntable Drive | 3/4 HP TEFC |

Weight and Size |

|

|---|---|

| Approximate Shipping Weight | 2948 kg (6500 lb) |

| Size | 5232 mm L 3886 mm W 3074 mm H (206″ L x 153″ W x 121 1/8″ H) |

Service Requirements |

|

|---|---|

| Pneumatic | 85-142 lpm @ 6Bar, 3-5 cfm @ 80 Psi, 4 Bar (55 Psi) |

| Dedicated Electric Service Req. | 3L-PE-400V-50Hz-No Neutral |

| Enclosure | NEMA 12 Enclosure with Disconnect and Safety Lock-out |

| Control | PLC wth HMI Touch Screen |

Warranty |

|

|---|---|

| 3 Year. Unlimited cycles. All components covered. |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.