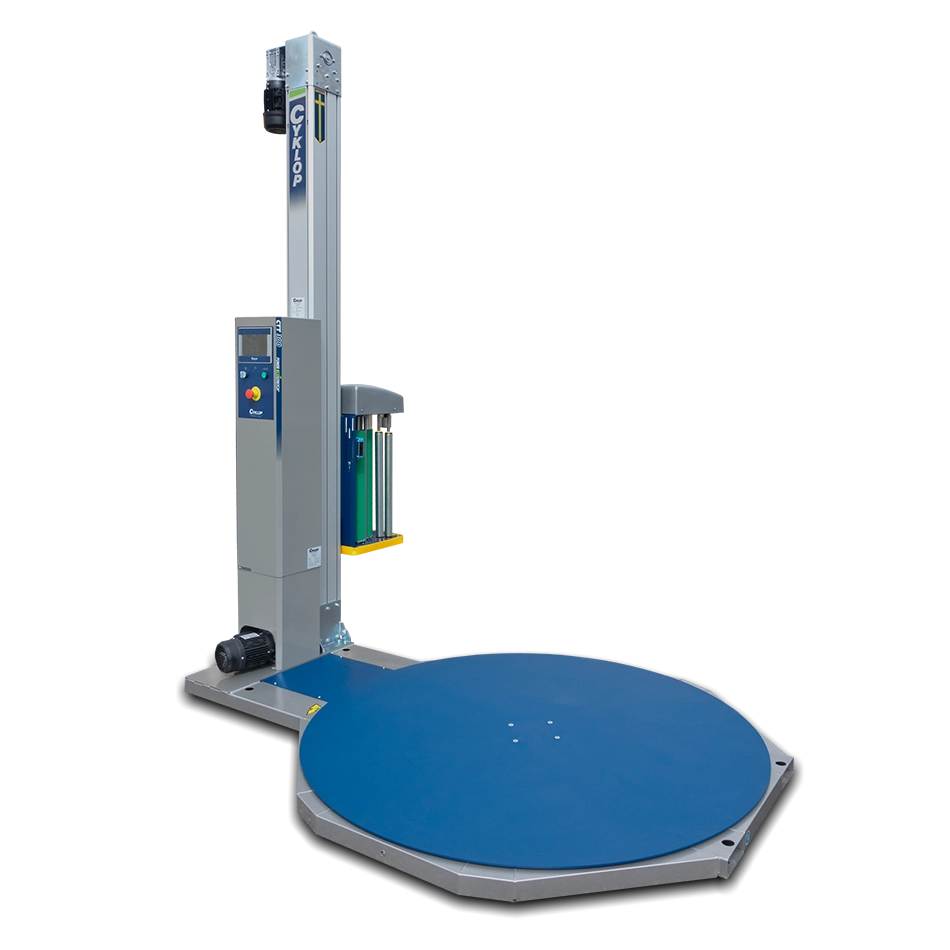

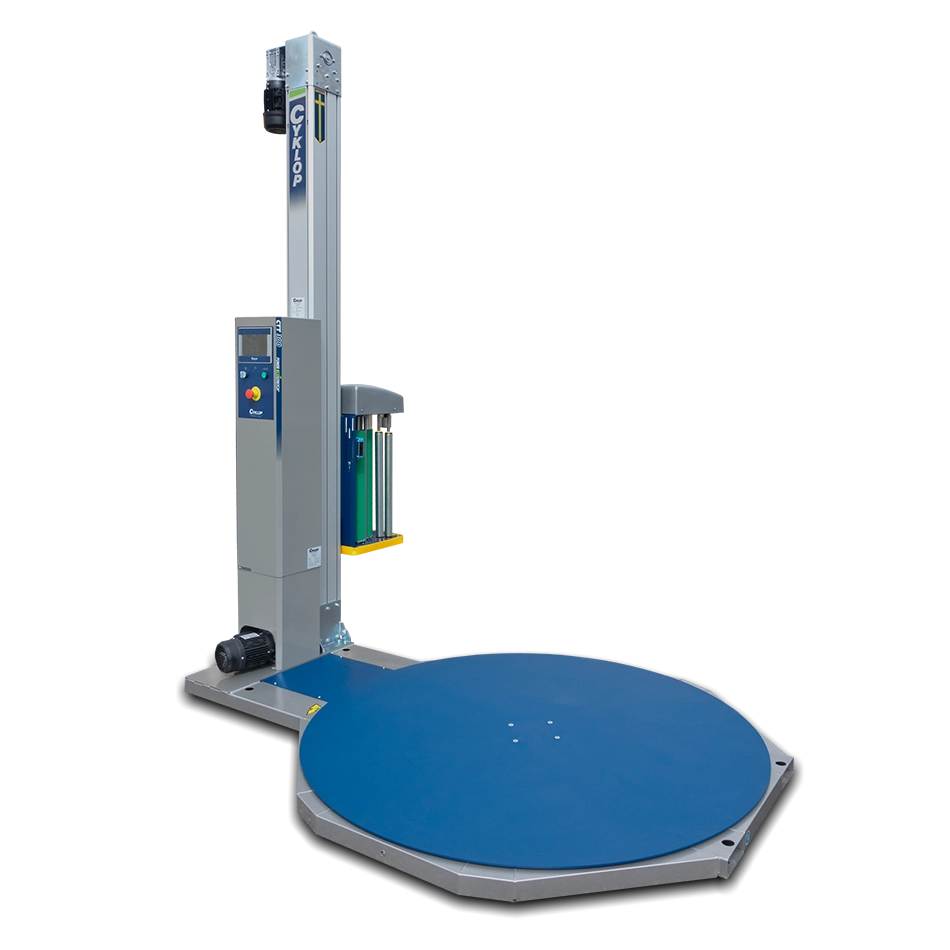

Introducing the CTT 300 turntable stretch wrapper – an ideal solution for stabilising 20 to 50 pallets per day. This advanced wrapper places products on a rotating turntable, wrapping them efficiently to secure loads. Designed for mobility, the CTT 300 can be easily relocated using a forklift, ensuring workspace flexibility.

Cyklop CTT 300

Fully automatic stretch wrapper with high processing speed for heavy-duty applications.

CTT 300 Stretch Wrapper

Equipped with an automatic cutting unit, the CTT 300 saves time and enhances ergonomics. Its user-friendly touch display simplifies operation, while a built-in sensor detects load heights up to 2200 mm. This high-quality Swedish machine is also upgradable with various options.

The unique “power-ecostretch” system achieves up to 400% pre-stretch, turning 1 metre of film into 5, reducing costs and environmental impact by up to 75%. Motor-driven pre-stretch rollers ensure stable wrapping for light and vulnerable pallets, making the CTT 300 a cost-effective choice that quickly pays for itself.

48″ Diameter Urethane Race

Provides broad balanced support and resists shock-loading meaning no metal-to-metal wear.

Microcontroller

- Intuitive, easy to understand controls regardless of language or skill

- Easily fine-tune wrap patterns with presets

Quick Reference Guide

- Located on the machine

- Includes trouble-shooting, operating, and adjustment guides

E-Z Thread Roll Carriage

- Rollers are fully shielded from hands

- Roll carriage on same side as controls, easy to load and reduces risk of injury

Features

- High Pre-Stretch Capability: Adjustable pre-stretch up to 400%, ensuring efficient use of wrapping film and stability for various loads.

- Integrated Cutting Unit: Automated cutting for improved efficiency and ergonomics.

- User-Friendly Interface: Easy-to-operate touch display with lockable features and nine adjustable wrapping programs.

- Load Detection: Automatic sensor for load heights up to 2200 mm.

- Mobility: Easily moved using a forklift, providing flexibility in warehouse operations.

- High Processing Speed: Enhanced wrapping speed for increased productivity.

Optional Extras for the Cyklop Stretch Wrapping Machine.

Specifications

| Turning Table | 1650 mm diameter |

| Maximum Pallet Dimensions | L1,200 x W1,000 x H2,200 mm |

| Maximum Pallet Weight | 2000 kg |

| Speed | Up to 15 rpm |

| Pre-stretch | 60% – 400% |

| Stretch Wrapping Programs | 9 Adjustable Programmes |

| Start / Stop | Frequency Controlled |

| FIlm | Core 76 mm Outer diameter 250 mm Width 500 mm |

| Protection | IP54 |

| Control | PLC |

| Power | 200-240 V / 50-60 Hz / 1 phase |

| Weight | 380 kg |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.