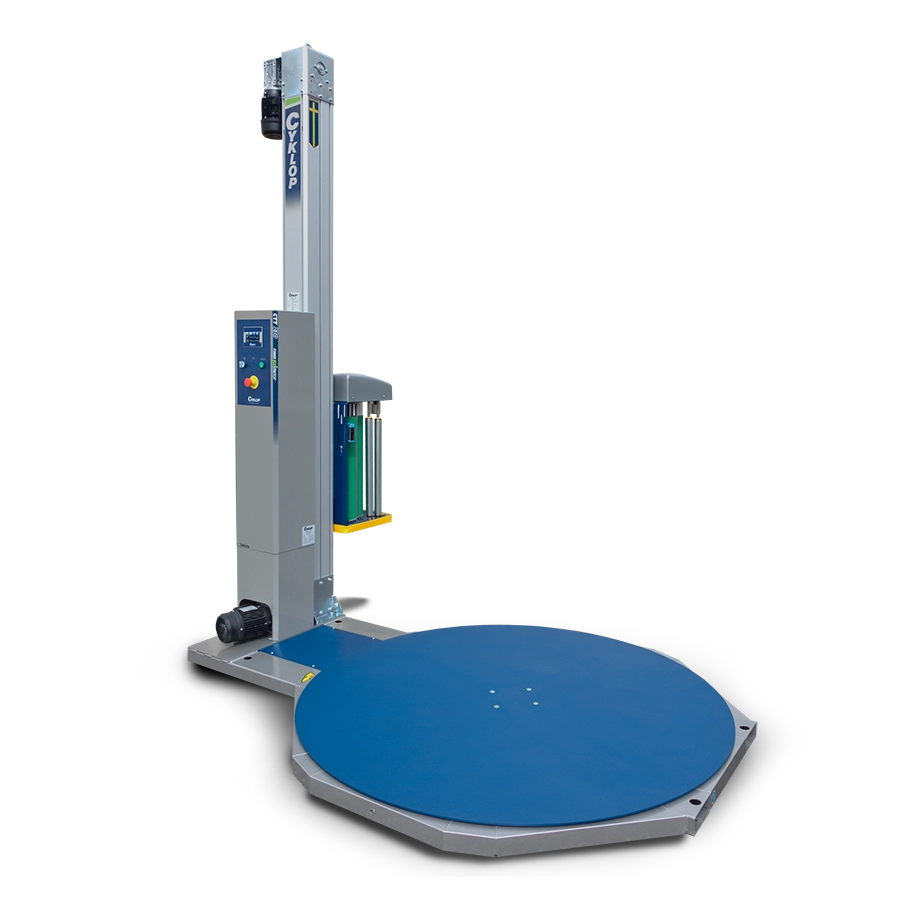

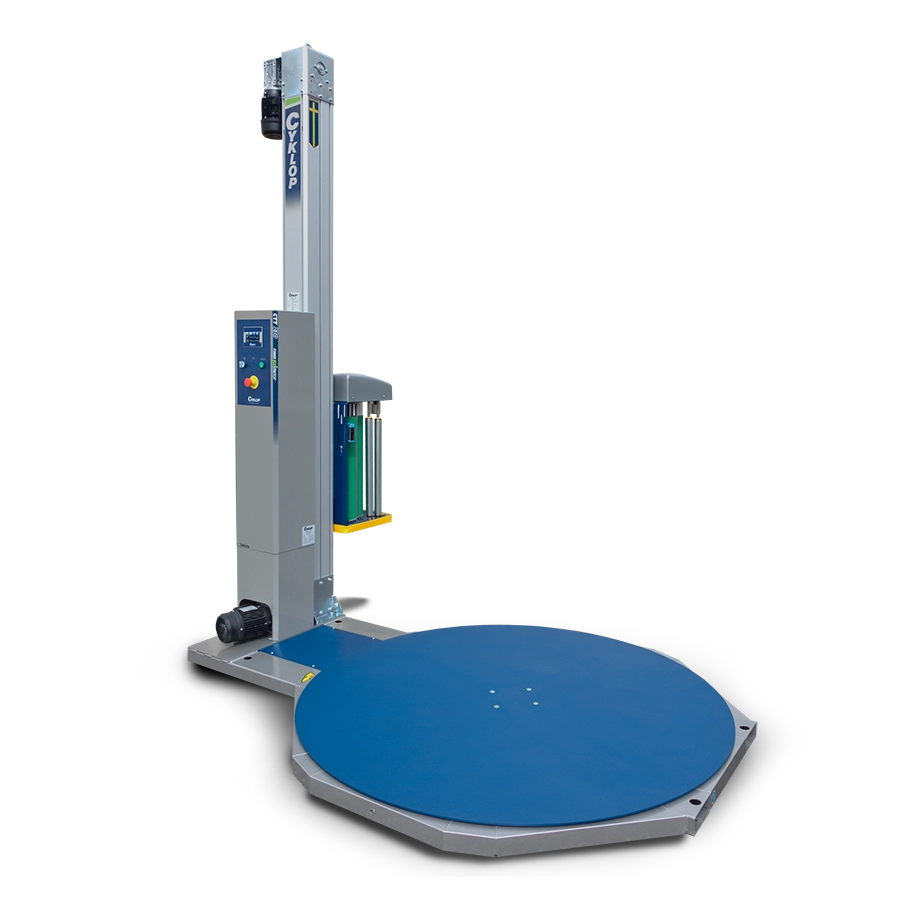

Enhance your packaging efficiency and protect your products with the Cyklop CTT230 Stretch Wrapping Machine. Engineered to simplify your pallet wrapping process, the CTT230 delivers robust performance and user-friendly operation, ensuring your shipments are securely wrapped and transport-ready. Perfect for various industries, this cutting-edge machine combines advanced technology with exceptional reliability, making it a crucial addition to any packaging line.

Cyklop CTT 230

Stretch Wrapping Machine capable of wrapping up to 40 pallets per hour.

CTT 230 Stretch Wrapper

Built to withstand the rigors of industrial environments, the CTT230 features a robust construction that ensures long-lasting performance. Its durable components and high-quality materials guarantee minimal maintenance and reliable operation.

Operation trough convenient rotary controls.

Cyklop’s patented ECOSTRETCH system with adjustable pre-stretch up to 400%*.

The safety photocells stops the machine if the beam is broken.

easy loading of turnable with palletjack. Ramp is removable and can be attached in three directions with our system (Left, right and front).

Features

- Advanced Stretch Wrapping Technology for precise film application, minimising waste and ensuring secure wrapping.

- High Pre-Stretch Capability: Adjustable pre-stretch up to 300%, ensuring efficient use of wrapping film and stability for various loads.

- User-friendly control panel simplifies setup and adjustment.

- Customisable wrapping programs to handle different packaging needs, from delicate items to heavy loads.

- Wrap up to 40 pallets per hour.

- Equipped with multiple safety mechanisms, including emergency stop functions and automatic load detection, to protect products and operators.

- Optimised for film usage and energy efficiency, the CTT230 supports sustainable packaging practices while maintaining high performance.

Optional Extras for the Cyklop Stretch Wrapping Machine.

Specifications

Machine |

|

|---|---|

| Table Diameter | 1650 mm |

| Speed | Up to 12 rpm adjustable |

| Start / Stop | Frequency Controlled |

| Bottom/ Top Wraps | 1–24 |

| Film Carriage Speed | Variable |

| Pre-stretch System | POWER ECOSTRETCH |

| Pre-stretch Ratio | 30, 60, 80, 110, 145, 200, 250 or 300 % Adjustable |

| Stretch Wrapping Programs | 4 Standard |

| Controller | PLC |

Power |

|

|---|---|

| Supply | Single phase 200-240V 50-60 Hz |

| Protection | IP54 |

| Loading | 10A |

Pallet Goods |

|

|---|---|

| Maximum Size | L 1200 x W 1000 mm |

| Maximum Goods Height including Pallet | 2200 mm |

| Permitted load Weight | 2000 kg |

Stretch Film |

|

|---|---|

| Core Diameter | 76 mm |

| Outer Diameter, Maximum | 250mm |

| Maximum Film Width | 500 mm |

| Film Thickness | 9-35 micron |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.