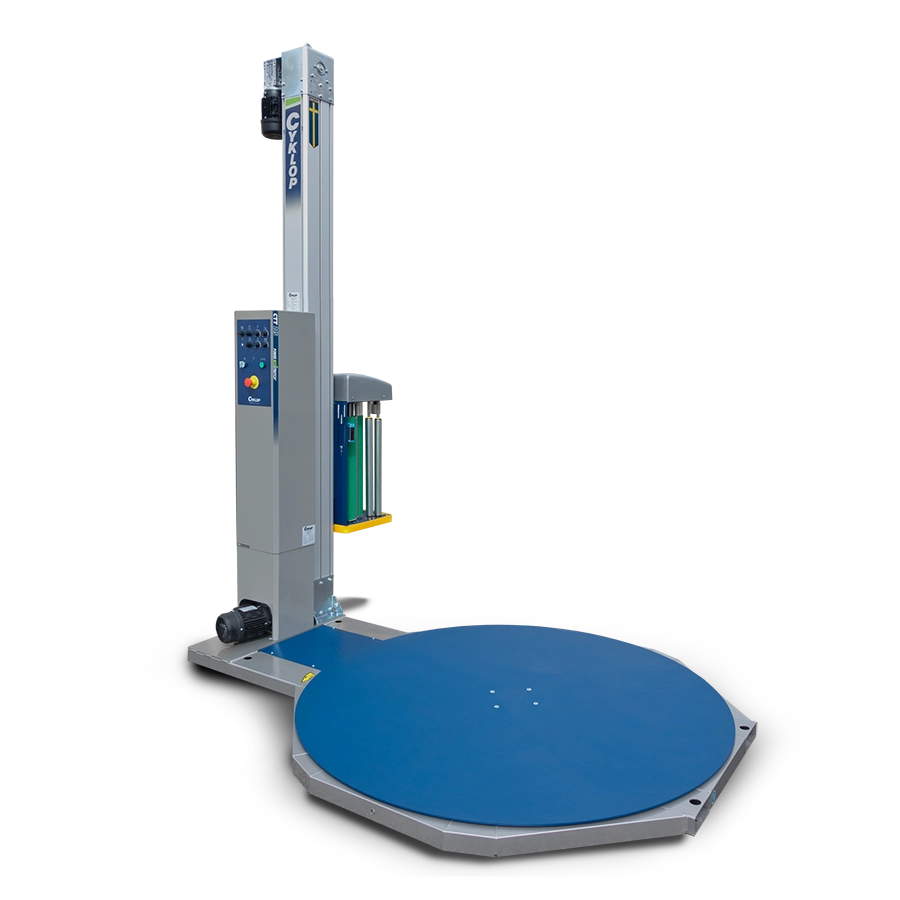

The Cyklop CTT 215 Stretch Wrapping Machine is a versatile and efficient solution for stabilizing and securing pallet loads. Designed for high throughput and low maintenance, this semi-automatic turntable wrapper offers cost-effective performance and ease of use. With its power pre-stretch unit and user-friendly controls, the CTT 215 ensures excellent load securement, enhancing transport safety and packaging efficiency. Whether you’re handling standard pallet sizes or unique load shapes, the CTT 215 is engineered to meet a variety of packaging needs.

Cyklop CTT 215

Enhanced-automatic stretch wrapper for medium to high-volume use.

CTT 215 Stretch Wrapper

The CTT 215 Stretch Wrapping Machine is designed to save costs by utilizing an adjustable pre-stretch ratio of up to 300% through its patented Echo StretchPlus system. This feature ensures consistent and low film consumption for each load. Additionally, the machine allows for individual adjustment of the film carriage speed to minimise overlap, and its motorised pre-stretch device further reduces film usage while providing protection for delicate goods.

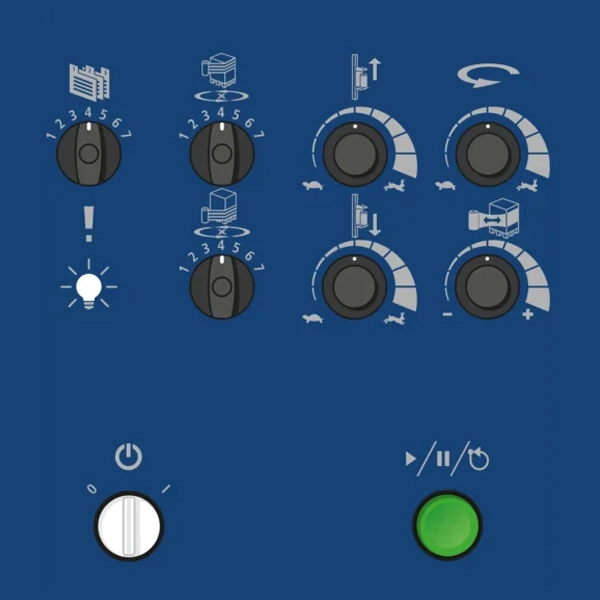

Operation trough convenient rotary controls.

Cyklop’s patented ECOSTRETCH system with adjustable pre-stretch up to 400%*.

The safety photocells stops the machine if the beam is broken.

easy loading of turnable with palletjack. Ramp is removable and can be attached in three directions with our system (Left, right and front).

Features

- Features a patented power pre-stretch unit that can stretch the film up to 300%, significantly reducing film consumption and ensuring consistent wrapping for every load.

- Capable of wrapping up to 40 pallets per hour.

- Equipped with convenient rotary controls and a simple, intuitive interface, making it easy to operate and adjust settings

- Five standard wrapping programs and one manual option, offering flexibility to handle various wrapping requirements.

- Adjustable film tension and speed to ensure even and secure wrapping.

- Designed for longevity, requires minimal maintenance, reducing downtime and operational costs.

- Includes a folding mast and forklift recesses, simplifying delivery and internal relocation.

- Quick and easy film change.

Optional Extras for the Cyklop Stretch Wrapping Machine.

Specifications

Machine |

|

|---|---|

| Table Diameter | 1650 mm |

| Speed | Up to 12 rpm adjustable |

| Start / Stop | Frequency Controlled |

| Bottom/ Top Wraps | 1–7 (Prog 3, 2-14) |

| Film Carriage Speed | Variable |

| Film Tension | Adjustable Friction Brake |

| Stretch Wrapping Programs | 5 Standard |

| Controller | PLC |

Power |

|

|---|---|

| Supply | Single phase 200-240V 50-60 Hz |

| Protection | IP54 |

| Loading | 10A |

Pallet Goods |

|

|---|---|

| Maximum Size | L 1200 x W 1000 mm |

| Maximum Goods Height including Pallet | 2200 mm |

| Permitted load Weight | 200 kg |

Stretch Film |

|

|---|---|

| Core Diameter | 76 mm |

| Outer Diameter, Maximum | 250mm |

| Maximum Film Width | 500 mm |

| Film Thickness | 9-35 micron |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.