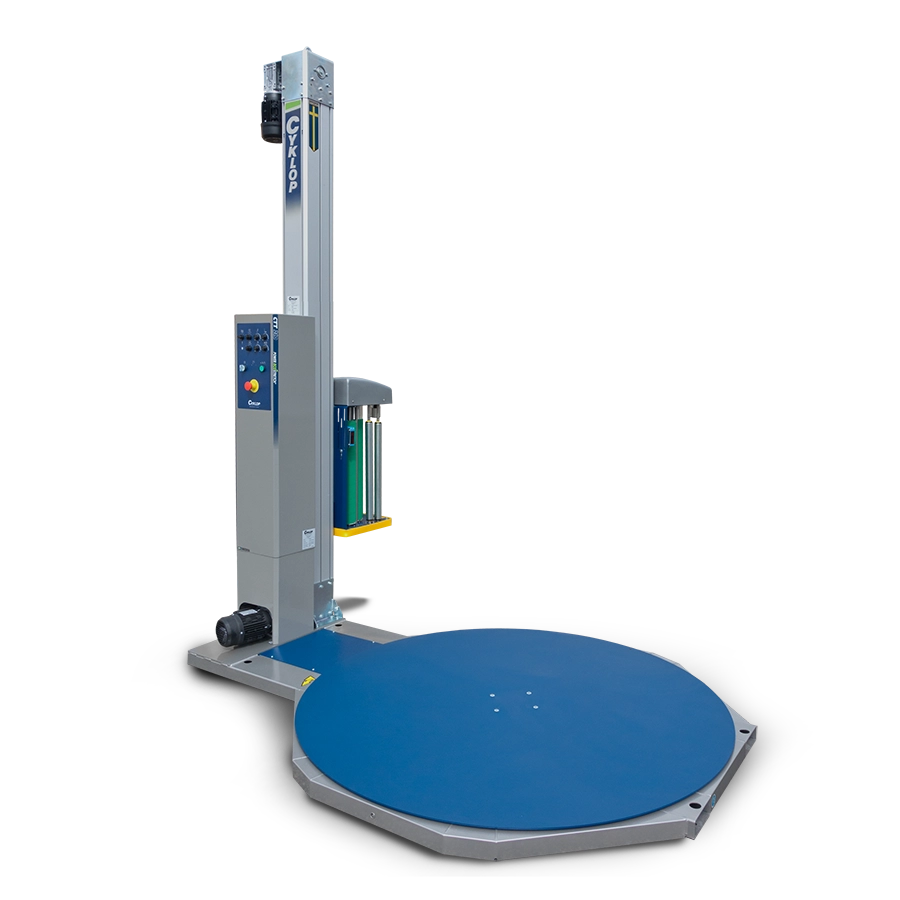

The Cyklop CTT 210 Stretch Wrapping Machine is a versatile and efficient solution for securing pallet loads. Designed for medium-duty applications, similar to CTT 200 but with enhanced features. It is perfect for users needing to wrap up to 50 pallets per day. Its simplicity and speed make it an ideal choice for businesses looking to enhance their packaging process. This semi-automatic turntable wrapper is built to handle irregular pallet loads with ease, ensuring both reliability and performance.

Cyklop CTT 210

Semi-automatic stretch wrapper for light to medium-duty applications with enhanced features.

CTT 210 Stretch Wrapper

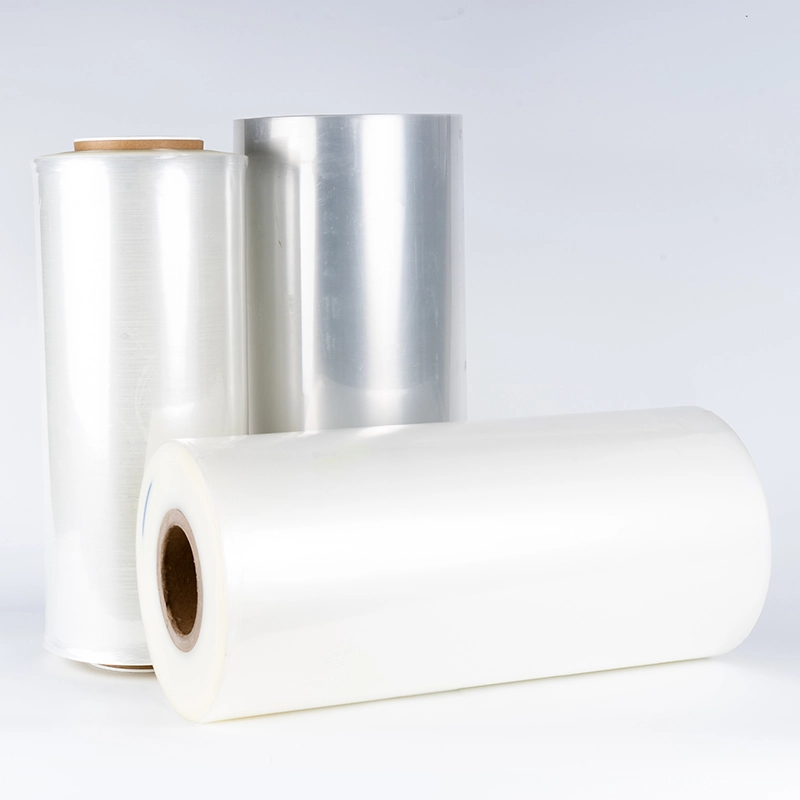

The CTT 210 Stretch Wrapping Machine is designed for cost efficiency, featuring an adjustable pre-stretch ratio of up to 235% with its patented Echo StretchPlus system. This ensures consistently low film consumption for each load. The film carriage speed can be adjusted to minimize overlap, and the motorized pre-stretch device further reduces film usage while protecting delicate goods.

48″ Diameter Urethane Race

Provides broad balanced support and resists shock-loading meaning no metal-to-metal wear.

Cyklop’s patented ECOSTRETCH system with adjustable prestretch up to 400%

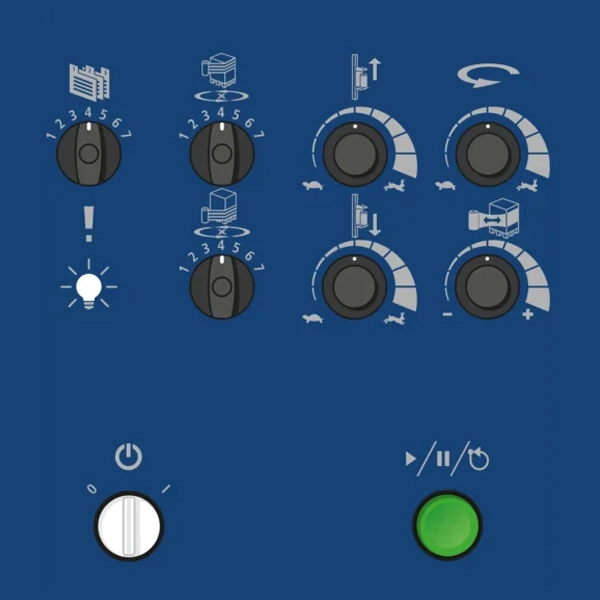

Quick Reference Guide

- Located on the machine

- Includes trouble-shooting, operating, and adjustment guides

E-Z Thread Roll Carriage

- Rollers are fully shielded from hands

- Roll carriage on same side as controls, easy to load and reduces risk of injury

Features

- Features a sophisticated pre-stretch system with adjustable ratios of 80%, 145%, and 235%. This allows for precise film stretching, ensuring minimal film usage and consistent load containment.

- Operators can individually adjust the film carriage speed to minimise overlap, optimising film usage and reducing costs while maintaining load integrity.

- Equipped with five standard wrapping programs and one manual option, providing flexibility to handle various load types and wrapping requirements.

- Wrapping speed of up to 12 rpm, the CTT 210 ensures quick and efficient pallet wrapping.

- Highly effective at wrapping irregularly shaped pallet loads, making it suitable for a wide range of applications.

- Advanced pre-stretch system helps reduce material costs significantly. This not only ensures cost savings but also supports sustainable packaging practices.

- Designed for longevity, requires minimal maintenance, reducing downtime and operational costs.

Optional Extras for the Cyklop Stretch Wrapping Machine.

Specifications

Machine |

|

|---|---|

| Table Diameter | 1650 mm |

| Speed | Up to 12 rpm adjustable |

| Start / Stop | Frequency Controlled |

| Bottom/ Top Wraps | 1–7 (Prog 3, 2-14) |

| Film Carriage Speed | Adjustable |

| Film Tension | Adjustable Friction Brake |

| Stretch Wrapping Programs | 5 Standard and 1 optional |

| Controller | PLC |

Power |

|

|---|---|

| Supply | Single phase 240V 50 Hz |

| Protection | IP54 |

| Loading | 10A |

Pallet Goods |

|

|---|---|

| Maximum Size | L 1200 x W 1000 mm |

| Maximum Goods Height including Pallet | 2200 mm |

| Permitted load Weight | 2000 kg |

Stretch Film |

|

|---|---|

| Core Diameter | 76 mm |

| Outer Diameter, Maximum | 250mm |

| Maximum Film Width | 50mm |

| Film Thickness | 9-35 micron |

Related Products

Frequently asked questions

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What is the recommended film tension for optimal pallet wrapping?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

What maintenance tasks are required to keep the Lantech Stretch Wrapping machine operating efficiently?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.

How can I troubleshoot film breaks during the wrapping process?

Lantech Stretch Wrapping machines typically offer adjustable tension settings to accommodate different wrapping needs. We recommend consulting the machine’s user manual or contacting Lantech support for specific tension recommendations based on your application.